The technology of 3D printing is at the tipping point of going “mainstream”, moving gimmicky toys to an integral part of modern industrial manufacturing processes, as well as end-user products. 2018 Winter International Technology & Management Business Plan Competition was held at Bayreuth of Germany from 3 to 12 January to learn about the latest development of 3D printing.

12 Dual Degree Program in Technology & Management (T&M-DDP) students formed mixed teams with students from University of Illinois at Urbana-Champaign of US, University of Bayreuth of Germany and University of Sao Paulo of Brazil. Each team made up of students from 4 universities was required to create a business plan involving 3D printing within the 8-day competition under the guidance of professors and industry mentors.

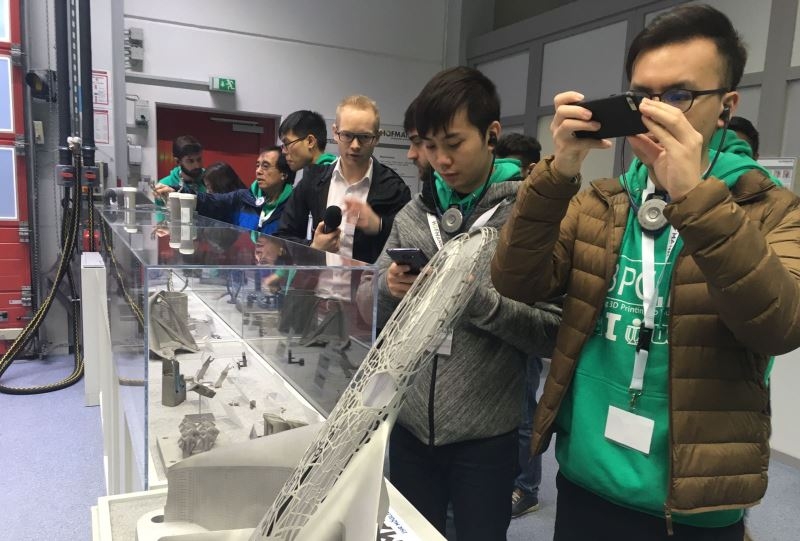

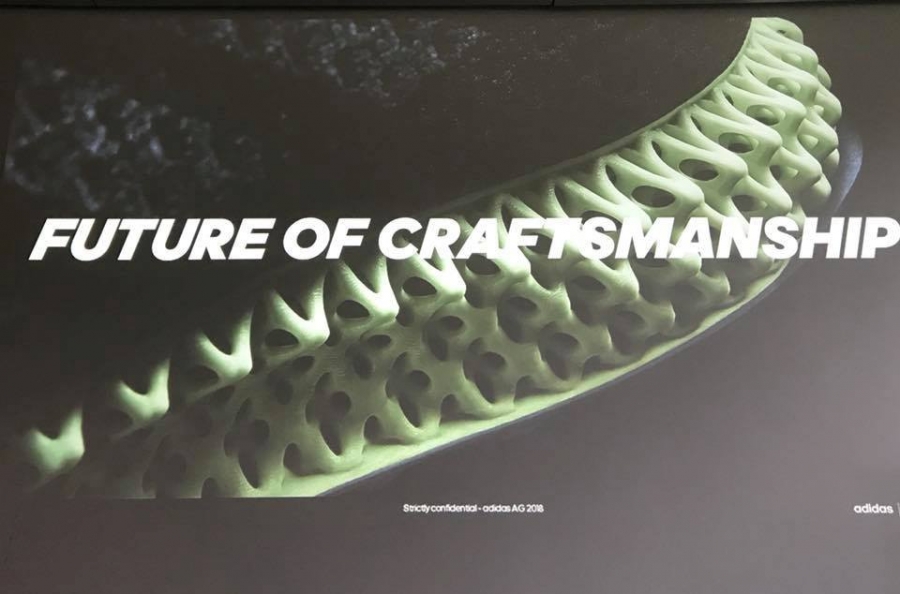

Students visited companies in Bavarian Germany and Prague Czech Republic involved in 3D printing applications including Neue Materialien Bayreuth, a non-academic research company developing various novel materials for lightweight constructions; Adidas, the world leading sportswear and accessories manufacturer; Hofmann, a world leader in automotive wheel service technologies, providing equipment for wheel balancing and tire changing, and Prusa, a 3D printer product manufacturer using 3D printers to produce 3D printers.

Experts in the field were invited to share their insights in 3D printing development and applications. Mr Bastian WEIMER, Channel Manager – Germany of Hewlett-Packard talked about the applications and limitations of current 3D printing technology. Mr Florian HORSCH, the Founder and CEO of HypeCask, a DIY Industrial Engineer and 3D-Printing Enthusiast, shared how he put 3D printing into business to provide consultancy and solutions services. Prof. Dietmar DRUMMER, Tenured Professor of the Institute of Polymer Technology, University of Erlangen-Nürnberg, explained the additive manufacturing process.

The winning team “Unum” created a personalized knife handle to ease the discomfort when using knives. Their target customers are professional chefs. They conducted an online survey with 130 professional chefs at Germany and found out that more than half of them felt regular discomfort using their knives. 65% of them were willing to pay for a more comfortable knife experience where they saw the business opportunity. The team proposed using sensor glove to find out pressure points when using knife and visualizing the pressure to understand the source of discomfort. They then would analyze the data and produce a clay model for further analyzing and fitting. With all those data and geometry analysis, a personalized knife handle would be printed by a 3D printer to fit for that particular customer.

The judging panel consisted of politicians, investors and industrialists to evaluate students’ performances from different perspectives. It’s a very tight race that the two next best teams who designed custom eye glass frames and custom baby pacifiers also impressed the judges with their high quality business plans. The investor judge found that many of the ideas proposed were indeed high potential for startup. This further reinforces T&M-DDP’s goal to drive the International Technology & Management Business Plan Competition becoming a great platform for students to learn the underlying ingredients for business success including hard work, ability to build trust across cultural differences, mastery of leading edge technology and also a bit of luck!